This note provides an example of how to set up Zubax Komar for use with Motres CIAG 100_30 KV80. Motres is a partner company of Zubax Robotics specializing in high-end PMSM motors.

The parameters of certain Motres motors, including CIAG 100_30 KV80, are available in the PMSM parameters spreadsheet:

The full set of configuration parameters for Komar is provided for convenience in the following files, each file containing a set of parameters pertaining to a particular function of the motor controller:

- Cyphal interface (edit to match the requirements of your application): telega_cyphal.yaml (1.5 KB)

- Komar-specific hardware parameters taken from the Komar documentation: telega_komar.yaml (358 Bytes)

- Parameters defined by the motor — Motres CIAG 100_30 KV80: telega_motres_ciag_100_30.yaml (3.6 KB)

Install Yakut as described in its README. Configure the environment variables per the CAN network configuration as described in the Yakut README. Store the configuration into an environment file; suppose it is named env_slcan.sh.

Connect Komar to the CAN bus; connect Zubax Babel to said CAN bus and to the PC via USB.

Launch the Yakut monitor with the plug-and-play node-ID allocator enabled:

source env_slcan.sh

y mon -P allocation_table.db

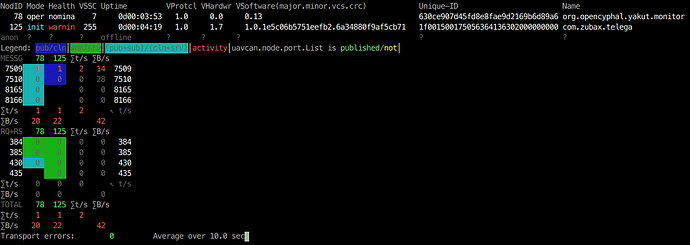

Keep the monitor running. In a few seconds it should display the Komar node. Take note of its node-ID in the leftmost column. In the example below, the node-ID of Komar is 125:

Download the YAML configuration files into the current directory. Upload all configuration files to Komar using a new terminal session, then restart the node:

source env_slcan.sh

cat *.yaml | y rb 125 # Replace 125 with the correct node-ID, or a range of node-IDs.

y cmd 125 restart # Ditto

The node will take a few seconds to store the new configuration and restart. Once it appears online in the Yakut monitor, the device is ready for use.

To enable analog control, the motor thermistor needs to be disconnected and the following registers need to be set:

aux.ctl.type: 1 # 0 - disable analog control; 1 - RCPWM; 2 - voltage control

aux.pull: -1

You can set registers individually as follows: y r 125 aux.pull -- -1

Restart the drive for the changes to take effect: y cmd 125 restart

DO NOT ENABLE ANALOG CONTROL IF CYPHAL CONTROL IS USED. This is because EMI from the drive may cause the analog interface to generate spurious control commands. Analog control is not recommended for use in drives with a maximum power exceeding 2 kW.