Electropermanent magnets are going to mostly replace conventional electromechanical grippers for payload attachment in drones and robots of all kinds. Instead of mechanically sophisticated claws, hooks, and locks, we’re moving toward purely solid-state solutions that hold payloads by magnetic attraction rather than mechanical interlocking.

When it comes to payload attachment, electropermanent magnets (EPMs) are quickly proving they’re not just an alternative — they’re a superior choice. Compared to conventional mechanical systems with moving parts, EPMs bring clear advantages in terms of safety and reliability. With no moving parts, EPMs entirely avoid issues of wear and tear. Unlike mechanical grippers, which can jam, seize, or lose strength over time, EPMs operate with consistent performance, even in the toughest environments. They’re built to hold or release payloads with a pulse of energy, after which they require no power to maintain their hold, making them safer and much more energy-efficient than conventional electromagnets.

A key feature of EPMs is that they require a ferromagnetic target for optimal grip. This is simpler than it sounds — many payloads are already ferromagnetic (especially in the defense domain); for those that aren’t, just add a small strip of steel for the magnet to latch onto, and you’re set. Alternatively, a mechanically minimalist cargo container for non-ferromagnetic or irregularly shaped payloads can be built with a lid at the bottom held by an EPM instead of a conventional electromechanical lock.

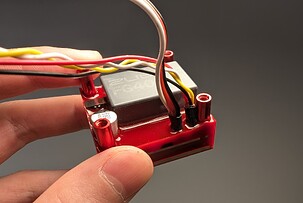

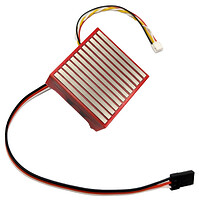

This approach isn’t just theoretical — it’s the future, and with FluxGrip, the future is already here. The pictures below show a small magnet sized just 4x4x2 cm that weighs 70 g and pulls up to 25 kgf—350 times its own weight!

The following live demo was recorded at an expo one week ago, where FluxGrip was first presented to a wide audience. The part where spectators were asked to tear the unpowered magnet off the steel plate usually caused mild astonishment:

As we continue developing, we’re not only focused on making EPMs the go-to solution for all types of unmanned vehicles but are also planning future versions of FluxGrip to cover a broader range of applications and integration possibilities. For example, one promising idea is integrating an EPM with high-bandwidth communication interfaces like Ethernet and wireless power transmission, allowing tight integration with data-intensive payloads or charging stations without any moving parts to manage.

In other words, magnetic grippers are about to become the norm, and FluxGrip is leading the charge. You can get a sample for evaluation today from the Cyphal Store or talk to us about your specific application by sending a message to sales@zubax.com.